Photoelectric

Testing needs in the Photoelectric Industry

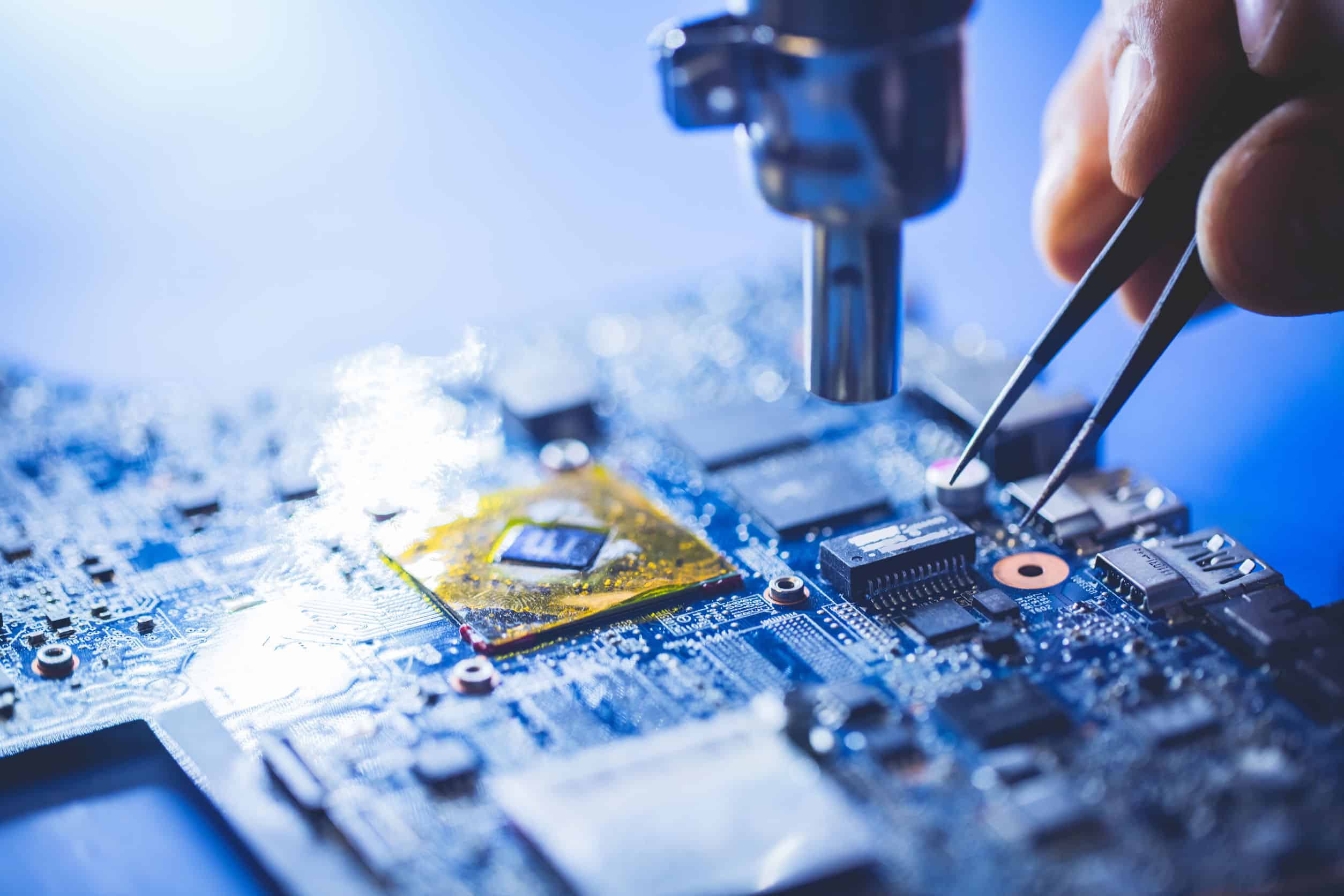

The Photoelectric Industry includes fields such as semiconductors, optical fiber communications, display technologies, and solar energy. Due to the high precision and quality required in these fields, various tests are necessary in the manufacturing process.

Among these, light resistance tests and transmittance tests are critical in product testing. Light resistance tests evaluate the durabilty of products under prolonged light exposure or high-energy light beams, ensuring that the products do not degrade or get damaged during normal use. On the other hand, transmittance tests is used to measure the barrier/permeability of materials to oxygen, water vapor, and carbon dioxide, which is crucial for the design and application of optical components.

In addition, concentration monitoring plays a significant role in the photoelectric industry. These systems monitor the concentration of etching solutions and adjust and maintain the liquid concentration on real-time data. This ensures the quality of finished products while reducing costs and waste.

How Can We Assist?

Concentration Monitoring System

Through the real-time monitoring of chemical concentrations using a Chemical Concentration Analyzer, it automatically adjusts the concentration when necessary, ensuring the quality of processing while reducing costs and minimizing waste.

Light Resistance Test

Simulating different light conditions to assess the durability and longevity of materials or products. Xenon arc Weather-Ometer / Fade-Ometer determines key characteristics of a product such as weather resistance, color retention, stability of physical properties. It can also use to predict when potential issues might occur during actual usage environment.

Transmittance Test

Whether it’s oxygen or water vapor, our permeation analyzers offer the lowest limits and the best repeatability in the market, ensuring that your new barrier membranes meet specification requirements. The Mocon Permeation Analyzers for ultra-high barrier materials are recognized as the global industry standard, offering high precision and repeatability for testing thin-film materials and final packaging designs. Through collaboration with the industry, Mocon has significantly enhanced the lifespan of OLED/FE (Thin Film Encapsulation).

Deaeration / Defoaming

Offering a variety of models from small to large capacity, non-vacuum and vacuum, and customizable fixtures to accommodate various types of containers, while simultaneously conducting material defoaming and stirring.

Nano-Pulverization

Nano Pulverizer crushes materials into extremely fine nano particles through high-speed rotating blades or spheres. It is critical in the manufacturing of nano-materials, nano-medicines, nano-coatings and nano-ceramics.

Popular Products

Lentex Advantage

35 yrs+ vertical integrated testing solution

End-to-end testing solution to meet customer needs at every stage

World-renowned testing instrument brands

Distributor for world-renowned testing brands and continue looking for latest testing technologies

Timely after-sales technical support

Our support engineers are highly experienced and knowledgeable who will provide timely technical support